|

Ball Mill Introduction

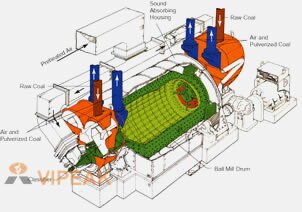

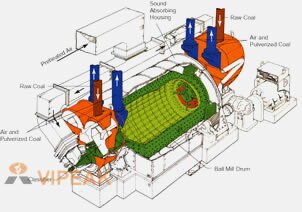

Ball mill, a type of Grinding Mill, is a cylindrical device used to grind (or mix) materials like ores, chemicals, ceramic raw materials and paints. The ball mill is a key equipment to grind the crushed materials after the material were broken , and carrying on the smashing again. It is divided into two rubbing way-the dry and the wet . Ball mill is mainly composed of charging and discharging, cyclone and rotation parts (like redactor, minor rotation gear, motor, electric machine, etc). Hollow axis is made of steel parts with a lining replacable. Major rotation gear, machined by rolling wheel of casting, is lined with wearing plate with fine wear-resisting property. This machine runs stably and reliably. Ball mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium. Different materials are used for media, including ceramic balls, flint pebbles and stainless steel balls.

Ball Mill Application

Ball mill is widely used in powder-making production line including cement industry, chemical industry, new building materials, fire-resistant materials, fertilizer, porcelain and glass industry for grinding iron ore, gold ore, concrete, slag, zinc, copper ore, tantalite, etc.The ball mill carries on the dry type or the wet powder to each kind of ore and other grindability material rubs

Features and Advantages:

1.Large application range, simple structure and convenient maintenance.

2.Large capacity and continuous work are very obvious.

3.Barrel lining and grinding media can apply various abrasive materials.

4.Installation and adjustment are very convenient and easy to be operated.

Working principle of ball mill :

Materials shall be evenly charged through quill shaft in feeding device into the first bin, which has step or waved lining with steel balls in different specifications. Steel balls are taken to a certain height by centrifugal force from drum rotation and then fall. Thus it will give a heavy blow to materials, playing a role of grinding. Materials after crushed in the first bin shall enter bin across single-layer diaphragm into the second, which is provided with flat lining with steel balls, to go through further grinding. Powder shall be discharged from discharging grating, ending the milling process.

Thanks for your interesting in our product Ball Mill. There are more than 10 Models of Ball Mill in our company, and the detailed specifications are as follows. If you have any question, please don't hesitate to contact us, we will provide you professional solutions.

Specification of Ball Mill:

| Model |

Rotary Speed

(r/min) |

balls weight(t) |

The feeding size

(mm) |

The finalsize

(mm) |

Capacity

(t/h) |

Main Motor

(kw) |

Weight

(t) |

| Ф900×1800 |

36-38 |

1.5 |

≤20 |

0.075-0.89 |

0.65-2 |

18.5 |

3.6~4.3 |

| Ф900×2400 |

36.4 |

2.1 |

≤20 |

0.075-0.89 |

0.65-3 |

18.5 |

4~4.8 |

| Ф900×3000 |

36 |

2.7 |

≤20 |

0.075-0.89 |

1.1-3.5 |

22 |

4.6~5.3 |

| Ф900×3500 |

36 |

2.7 |

≤20 |

0.075-0.89 |

1.1-3.8 |

22 |

5.2~5.8 |

| Ф1200×1200 |

36 |

1.5 |

≤25 |

0.075-0.6 |

1.2-3 |

22 |

8.5 |

| Ф1200×2400 |

36 |

3 |

≤25 |

0.075-0.6 |

1.5-4.8 |

30 |

11.4 |

| Ф1200×3000 |

36 |

3.5 |

≤25 |

0.075-0.4 |

1.6-5 |

37 |

12.1 |

| Ф1200×3500 |

32.4 |

5 |

≤25 |

0.075-0.4 |

1.6-5.2 |

55 |

12.7 |

| Ф1200×4500 |

32.4 |

5 |

≤25 |

0.075-0.4 |

1.6-5.8 |

55 |

13.1 |

| Ф1500×3000 |

29.7 |

7.5 |

≤25 |

0.075-0.4 |

2-5 |

75 |

14.8 |

| Ф1500×3500 |

29 |

9 |

≤25 |

0.075-0.4 |

2-6 |

95 |

15.8 |

| Ф1500×4000 |

29 |

10 |

≤25 |

0.075-0.4 |

3-7 |

110 |

17.9 |

| Ф1500×4500 |

27 |

11 |

≤25 |

0.075-0.4 |

3-8 |

110 |

19.9 |

| Ф1500×5700 |

28 |

12 |

≤25 |

0.075-0.4 |

3.5-8.5 |

130 |

23.4 |

| Ф1500×6400 |

28 |

16 |

≤25 |

0.075-0.4 |

3.5-9 |

155 |

25.4 |

| Ф1830×2400 |

25.4 |

10 |

≤25 |

0.075-0.4 |

4-10 |

130 |

23.7 |

| Ф1830×3000 |

25.4 |

11 |

≤25 |

0.075-0.4 |

4-10 |

130 |

26.6 |

| Ф1830×3600 |

25.4 |

13 |

≤25 |

0.075-0.4 |

4.1-10.5 |

130 |

27.6 |

| Ф1830×4000 |

25.4 |

15 |

≤25 |

0.075-0.4 |

4.3-11 |

155 |

29.4 |

| Ф1830×4500 |

25.4 |

15 |

≤25 |

0.075-0.4 |

4.5-12 |

155 |

30.4 |

| Ф1830×6400 |

24.1 |

21 |

≤25 |

0.075-0.4 |

6.5-15 |

210 |

32.3 |

| Ф1830×7000 |

24.1 |

23 |

≤25 |

0.075-0.4 |

7.5-17 |

245 |

34.2 |

| Ф2100×3000 |

23.7 |

15 |

≤25 |

0.075-0.4 |

6.5-36 |

155 |

32.3 |

| Ф2100×3600 |

23.7 |

18 |

≤25 |

0.075-0.4 |

6.5-38 |

210 |

33.8 |

| Ф2100×4000 |

23.7 |

21 |

≤25 |

0.075-0.4 |

6.5-40 |

210 |

35 |

| Ф2100×4500 |

23.7 |

24 |

≤25 |

0.075-0.4 |

8-43 |

245 |

40 |

| Ф2100×7000 |

23.7 |

26 |

≤25 |

0.075-0.4 |

8-48 |

280 |

47.5 |

| Ф2200×4500 |

21.5 |

27 |

≤25 |

0.075-0.4 |

9-45 |

280 |

46.5 |

| Ф2200×5500 |

21 |

30 |

≤25 |

0.075-0.4 |

10-22 |

370 |

48.5 |

| Ф2200×6500 |

21.7 |

35 |

≤25 |

0.075-0.4 |

14-26 |

380 |

50.2 |

| Ф2200×7000 |

21.7 |

35 |

≤25 |

0.075-0.4 |

15-28 |

380 |

51.3 |

| Ф2200×7500 |

21.7 |

35 |

≤25 |

0.075-0.4 |

15-30 |

380 |

53.2 |

| Ф2400×3000 |

21 |

23 |

≤25 |

0.075-0.4 |

7-50 |

245 |

51.3 |

| Ф2400×4500 |

21 |

30 |

≤25 |

0.075-0.4 |

8.5-60 |

320 |

61.7 |

| Ф2700×2100 |

20.7 |

23 |

≤25 |

0.075-0.4 |

8.5-17 |

260 |

49 |

| Ф2700×3600 |

20.7 |

37 |

≤25 |

0.075-0.4 |

11-27 |

400 |

79 |

| Ф2700×4000 |

20.7 |

40 |

≤25 |

0.075-0.4 |

12-80 |

400 |

89 |

| Ф2700×4500 |

20.7 |

48 |

≤25 |

0.075-0.4 |

12-90 |

430 |

97 |

| Ф3200×3000 |

18.6 |

46 |

≤25 |

0.075-0.4 |

15.5-33 |

500 |

112 |

| Ф3200×3600 |

18.6 |

56 |

≤25 |

0.075-0.4 |

17.5-40 |

630 |

118 |

| Ф3200×4500 |

18 |

65 |

≤25 |

0.075-0.4 |

8.5-60 |

800 |

130.5 |

| Ф3600×3900 |

17.8 |

75 |

≤25 |

0.075-0.4 |

25-53 |

1000 |

152.9 |

| Ф3600×4500 |

17.8 |

88 |

≤25 |

0.075-0.4 |

29-65 |

1250 |

165 |

| Ф3600×6000 |

17.8 |

117 |

≤25 |

0.075-0.4 |

35-80 |

800 |

196 |

| Ф4000×5000 |

16.4 |

101 |

≤25 |

0.075-0.4 |

46-97 |

800 |

248 |

|